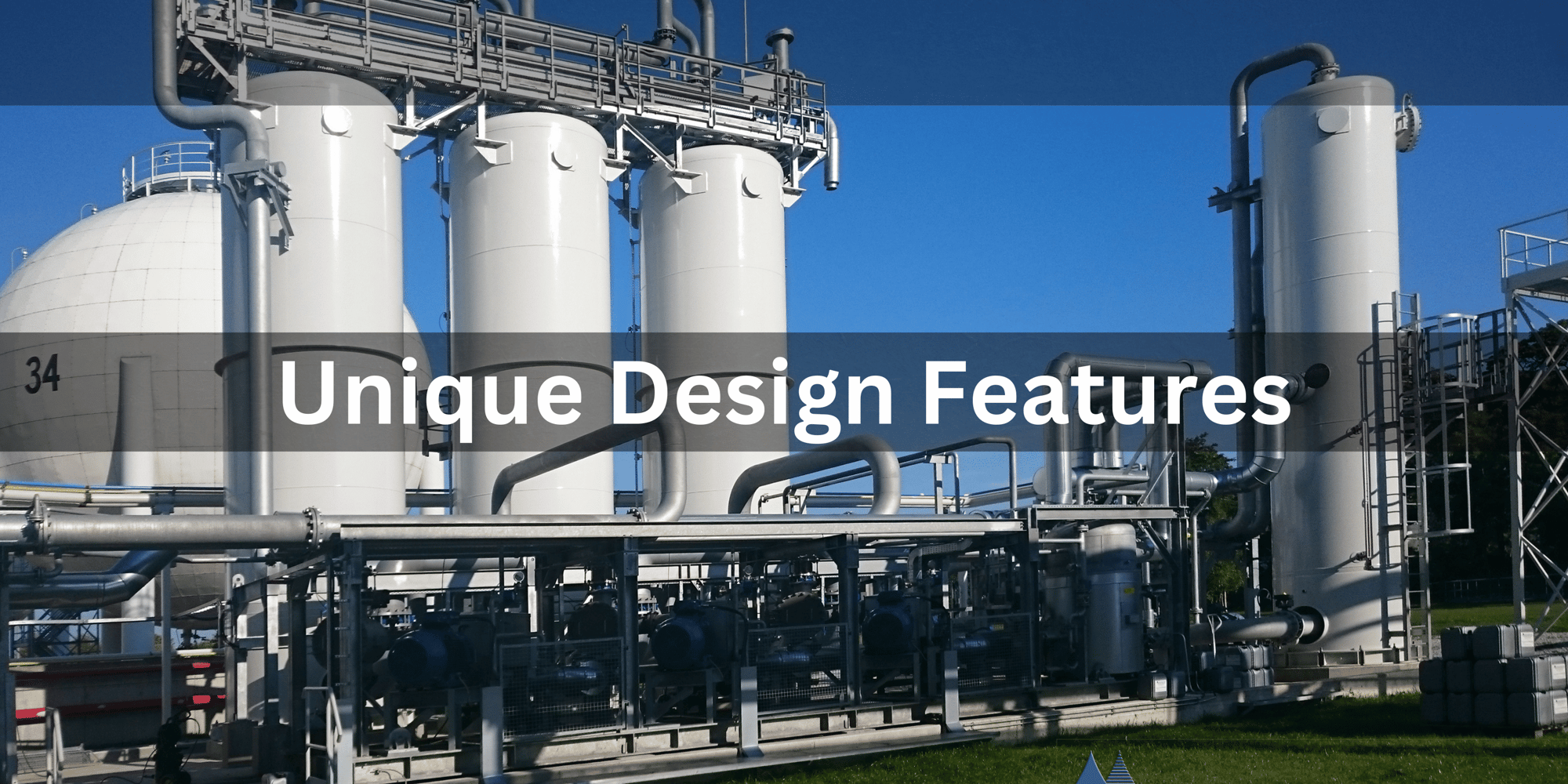

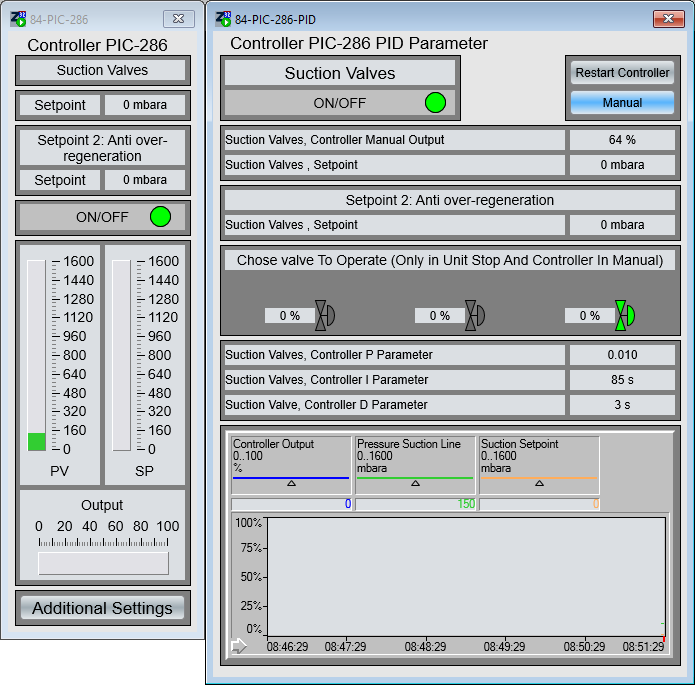

Advanced Vacuum Control for Minimal Power Consumption

In Cool Sorption, we use a highly efficient vacuum system with low pressure loss in the suction lines as well as an advanced and well-tested control system. Both ensure maximum suction during evacuation and regeneration, thus minimising the power consumption.

.png)

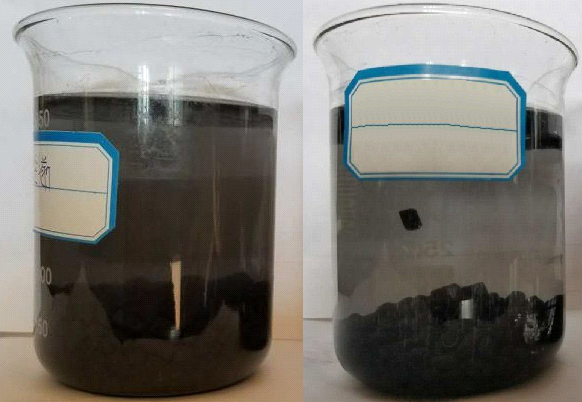

High Duty & Long Life Activated Carbon

Our mineral based, activated carbon is extremely high duty with excellent adsorption and regenerative properties. The extremely open pored structure increases the lifetime compared to more traditional carbon. Our carbon is pelletized, giving much higher physical stability than granular carbon, thus minimising dust tendency and giving long lifetime of the carbon.

Optimal Carbon Bed Design

An advanced hold down arrangement on top of the activated carbon prevents movement of the bed during equalization. The formation of dust from friction as well as uneven distribution of the activated carbon is thereby prevented, which would otherwise have resulted in a lower actual capacity of the unit.

-2.png)

Dedicated System for Pressure Equalisation

A unique, but simple equalisation system with separate equalisation valves gives a very well defined equalisation flow compared to other systems where equalisation is done using a very small opening of the normal vapour inlet valve to the carbon bed. These separate equalisation valves gives a more well controlled equalisation flow, which minimises friction on the activated carbon giving increased carbon lifetime.

%20(3).png)

Dry Vacuum Pumps

The use of highly efficient and reliable rotary vane vacuum pumps results in a 25-30% lower power consumption than traditional liquid ring pumps, as well as no glycol waste disposal concerns, a simpler piping system and simplified maintenance. The rotary vane pump is also much more robust and easy to operate correctly than the screw pump and has a much lower investment cost, making the rotary vane pump the preferred choice both technically and economically.

.jpg)

No Ladders or Platforms for DS-Series

For our DS-seriesTM, all valves are located at skid level, eliminating the need for ladders and platforms to the top of the carbon beds. This reduces both installation time and price. It also improves the access and safety for operators and maintenance teams, as all activities can be conducted from ground level.

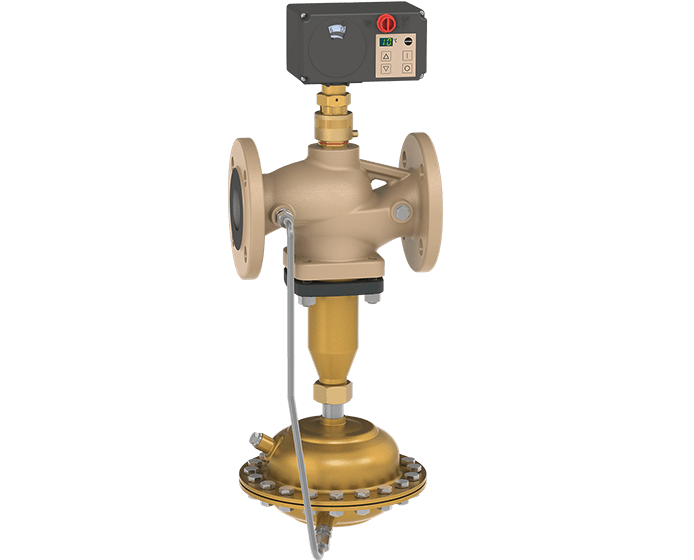

Absorber Flow Control for Uneven Absorbent Conditions

An automatic flow control valve compensates any instability in the absorbent supply to the unit. This allows our clients to have a wide range of pressure conditions at the absorber inlet without worrying about affecting the absorption process.

Zero Pressure Loss

An extraction fan at the AC vessel outlet compensates for all pressure losses in the VRU system, avoiding overpressure in the system and often reducing the necessary vapour inlet pipe size. In most cases, the extraction fan excludes the need for a certified Zone 0 vapour transport blower in the vapour header.

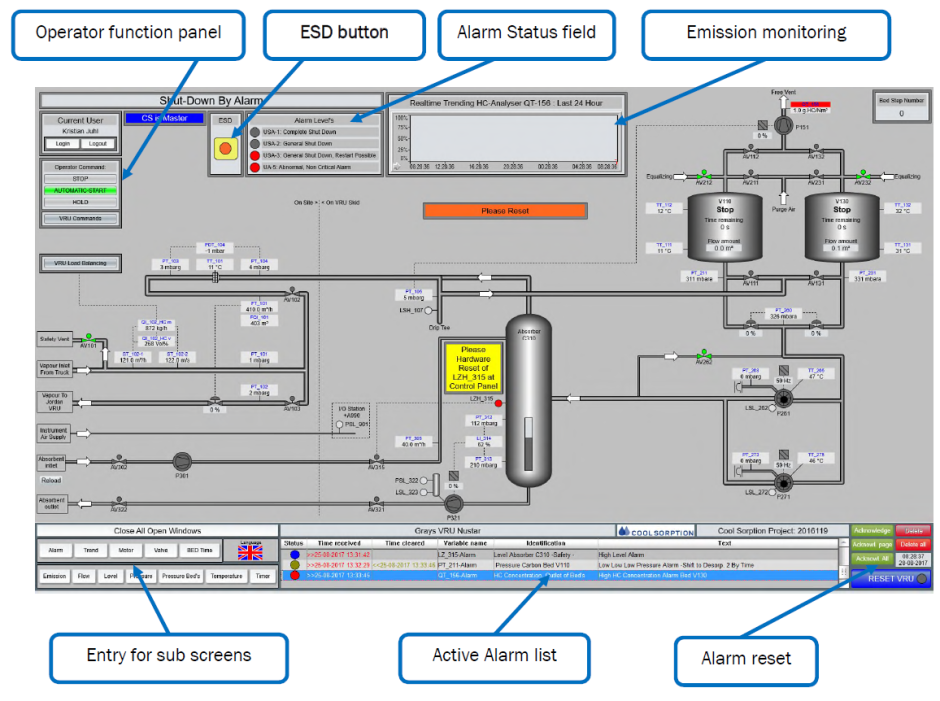

Remote Access from Cool Sorption’s Maintenance Centres

The operator PC can be connected via secure modem to Cool Sorption service department for easy diagnostics of any problems which might occur.

Safe VRU Design Pressure

Although the VRU operates at close to atmospheric conditions, an extra degree of safety is built in by designing all pressure vessels and piping to withstand higher pressures. All vessels are tested at a minimum of 10 barg, and are supplied with material certificates, and all piping is hydraulically tested to 13 barg. This makes the VRU able to withstand high internal pressure, ensuring extreme safety. There have been no recorded safety incidents for Cool Sorption VRUs in over 25 years.

Safe design, Documented in a Hazard and Operability Study (HAZOP)

Cool Sorption is able to offer a complete HAZOP study or qualified assistance in HAZOP sessions, covering the VRU itself and all related vapour and absorbent systems.

.png)

Service and Maintenance Agreements

Cool Sorption has a long tradition of contractual maintenance agreements of many different types, ranging from planned, preventive maintenance to the total responsibility of the VRU operation, often in cooperation with local partners. About 75% of all installed Cool Sorption units are covered by a service agreement.

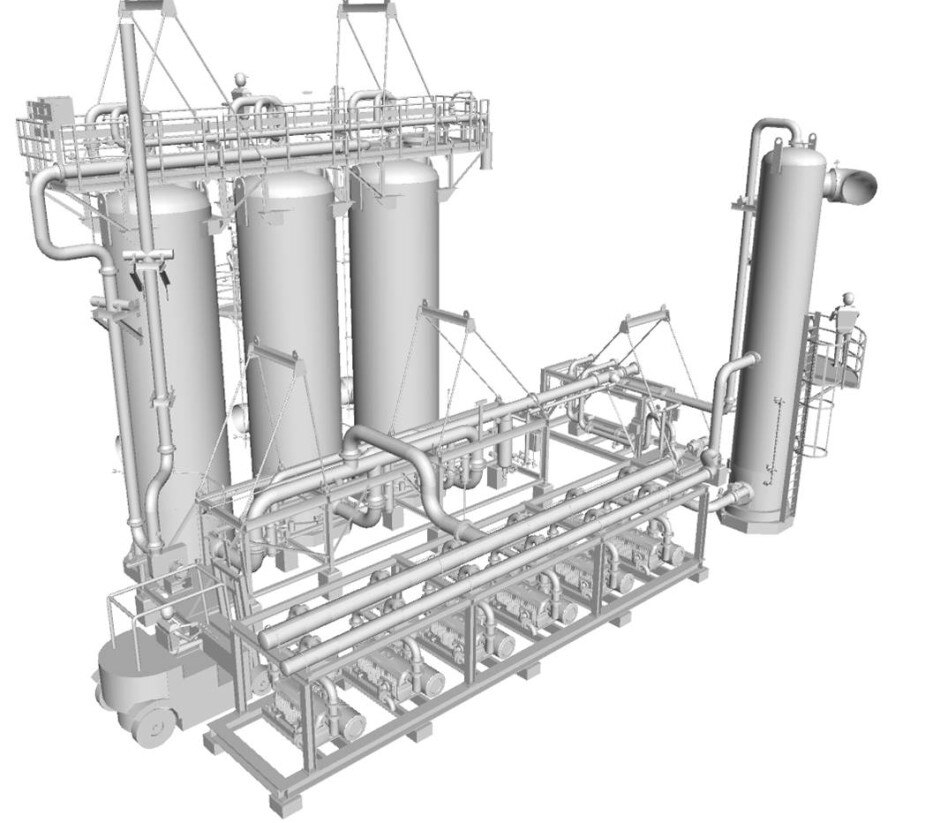

Highly Advanced Design Tools

At Cool Sorption, we use a mix of self-developed programs and industrial software to accurately design the unit: CAD for 3D plant design, process simulation software for overall plant design and specialised software for absorber column and activated carbon bed design.

Standard Energy Saving Mode

All our units has the option of using a highly advanced energy saving mode, utilising loading signal and VOC measurement at vent outlet to control the system in order to strongly reduce energy consumption during low operational activities.

Triple-Cleaned Activated Carbon and Laboratory Test of Activated Carbon

All our activated carbon is triple cleaned by the supplier in order to minimise the dust content of the carbon filled into the carbon filters. We also test a sample of all purchased activated carbon in order to ascertain correct capacity, mechanical strength and dust content of the carbon. This ensures the expected high quality of the loaded carbon and prevents expensive maintenance and downtime later in case of dust in the system or too high hydrocarbon emission.

VOC Emission Measurement

All Cool Sorption VRUs are supplied with VOC measurement system at vent outlet for continuous emission control and logging. Optional measurement of CO in the vent outlet is also possible.

.jpg)

Proprietary 3-Bed Solution for TS-Series

Our TS-series is designed with our proprietary carbon bed adsorber design configuration, utilizing three carbon beds. This unique configuration offers the following distinct advantages compared to the traditional 2-bed VRU.

Ready to talk?

Let us know how we can help you out, and one of our experts will be in touch right away.