%20(1).png?width=2000&height=1500&name=Add%20a%20heading%20(3968%20x%202976%20px)%20(1).png)

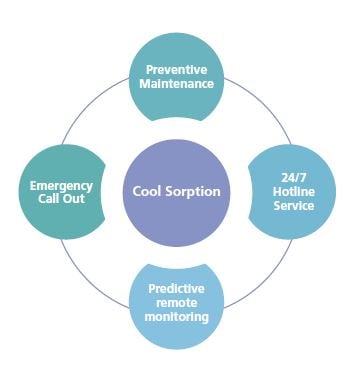

We cover your service needs

Cool Sorption offer a range of extensive after-sales service agreements for all types of vapour recovery units. Aiming at preventive maintenance, most of our vapour recovery units are covered by service agreements ensuring the required emission control limits and reducing the risk of unplanned downtime. The service is performed by our own trained and experienced service engineers and covers:

- Start-up, commissioning, capacity and capacity testing

- Training of terminal personnel in operation of the vapour recovery unit

- Preventive service check and overhaul of Cool Sorption’s or other supplier’s units

- 24 hour emergency hot-line to ensure availability

- On-line diagnostics and availability reporting to document compliance to local regulations

- Service visit with replacement of defective parts on site

Cool Sorption your service partner

Have you considered entering into a service agreement and optimising the operation of your Vapour Recovery Unit? The right service is a question of combining your service requirements with the most suitable maintenance approach, so that you will get an optimum and profitable result. We suggest that the choice of service concept is considered at an early stage, while investing in your new VRU. Of course, it is always possible to enter your VRU, of all brands, into a service agreement at any stage of its lifecycle.

Our service concept

Service and maintenance are provided by our skilled service engineers who utilize the collected competences from our experienced service team. Our portfolio of service support options

leverages this expertise to assist you throughout the service lifecycle.

At Cool Sorption, we have made it a key topic to clarify and cover your service needs. We contribute to everyday safety of your site. We know uptime is crucial to your business and that your unscheduled downtime needs to be minimized. Our flexible service agreements are designed to comply and exceed your expectations.

Some of the services that we can offer:

We have carefully crafted packages to help you save costs and ensure a quick implementation process:

✅ECO-mode to save energy

✅SCADA and PLC upgrade packages

✅Instrument replacement packages

✅Pump renovation or upgrades

✅Active Carbon replacement (we are performing carbon capacity tests before advising for replacement)

Ready to talk?

Let us know how we can help you out, and one of our experts will be in touch right away.